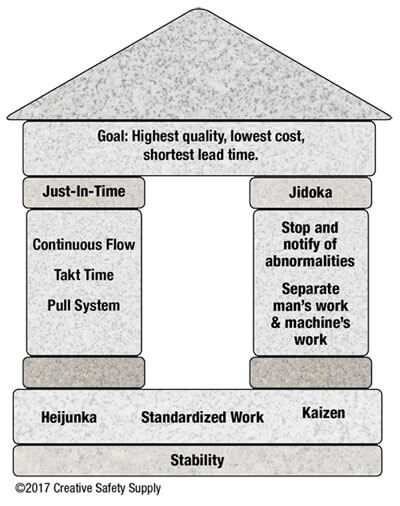

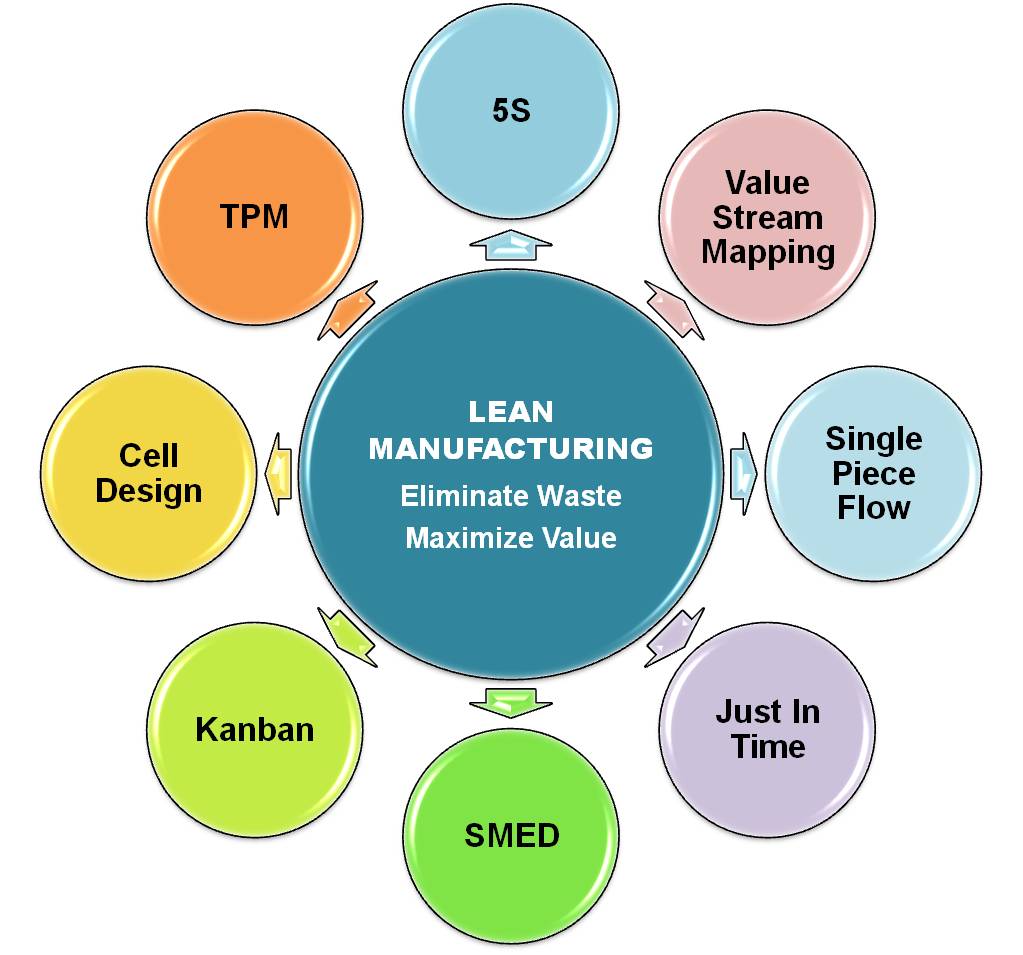

Overprocessing or incorrect processing causes waste and rework.Overproduction produces inventory that must be stored until needed.There are seven major types of non-value added work: Problem solving is 20% tools and 80% thinking.The only thing that adds value is the physical or informational transformation of raw material into something the customer wants.Material, parts, and products are impatient. One-piece flow increases productivity, profitability, and quality.Continuously solving root problems drives organizational learning.Developing your people and partners adds value.The right process will produce the right results.Here's Toyota's critical discovery: When you make lead times short and focus on keeping production lines flexible, you actually get better quality, responsiveness, productivity, and utilization of equipment and space. The visual ability to see low stock and replenish it became known as the kanban (a.k.a. In a pull system, the preceding process must always do what the subsequent process tells it. they saw how supermarket shelves held minimal inventory and were replenished only as quickly as customers "pulled" the products off the shelf. It's about shrinking batch sizes down to create a "one-piece flow."Īnd where did Toyota get this silly idea called "lean?" From U.S. It's about eliminating non-value added elements from the process.

LeanĪt it's heart, lean is about speed and the relationship between steps in a process. Each is a slightly different view through a different facet of the same diamond.

Toyota lean manufacturing iso#

So are all of the quality disciplines whether it's ISO 9000 or software's CMMI. Six Sigma and Lean are clearly on a collision course. And it seems to work well: Toyota's profits in March 2003 were larger than GM, Ford, and Chrysler combined! It's also known as the Toyota Production System or TPS for short. Go Deeper: Toyota invented "lean production" according to Jeffrey Liker, author of The Toyota Way. Lean Six Sigma Articles » Lean Six Sigma Want to Know Enough About Lean Six Sigma to Get Started? With QI Macros and training in seven key tools, you can start making improvements in a day or two.

Toyota lean manufacturing free#

Statistical Analysis - Hypothesis Testing.

0 kommentar(er)

0 kommentar(er)